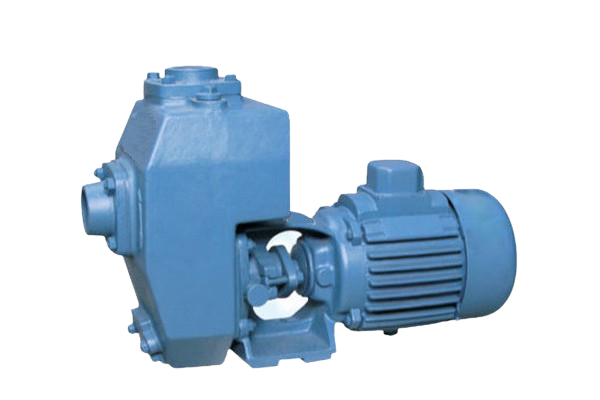

Mud Pump Manufacturer and Supplier in India

We are affianced in offering a comprehensive range of Mud Pumps in India. Manufactured using modern equipment, Mud pumps are high-performing, easy to install, and have a long service life. The mud Pump is attached with a complete set of mixers as well as pumps. These Mud Pumps are recommended for stability, and high effectiveness and are designed for the movement of drilling fluid & other corrosive chemicals.

Mud Pumps are accessible in different sizes and shapes and are widely suitable for the industry. We manufacture and supply mud pumps such as self-priming mud pumps, self-priming mud mono pump sets, c.i. self-priming mud pump, ss self-priming mud pump, ss – 316 self-priming mud pump, c.i. mud pump, ss mud pump, ss – 316 mud pump, self-priming bare mud pumps, and hydraulic mud pumps in India.

Operation Advantage of Self-Priming Mud Pump

- Pump is designed to retain the liquid at suction side of the casing to operate the pump as self priming

- Sufficient space is maintained to handle the solids

- First time priming is require to remove the air

- Generally self priming is upto 5 metre

- Foot valve is not required

Application

- Polluted liquid, muddy water or fresh water

- Dewatering basements trenches.

- Swimming pools construction sites onboard shifts as blidge for desk wash & engine colling.

- Tiles and marbles factories.

- Any application where priming is to be avoided.

Special Features

- Excellent quick automatic action without foot valve up to 7 meters.

- Automatic air release during priming.

- Back pull out design, so easy maintenance without disturbing pipelines.

- Dynamically balanced rotating parts ensure less vibrations.

- Better efficiency because of good hydraulic design.

- Minimum parts, fast repairing at low cost, also pump is available at economical rate.

- Available in Bare, Coupled, Mono-block, Belt driven & Engine driven version.

- Also offered pump with trolley / trailer to move it from one place to another.

- Mono-block pumps can be able to with stand with wide voltage fluctuations.

- Less expensive & easily available spares.

- Pumps can be fitted with mechanical seal as per customer’s requirements.

- Very simple construction, only two moving parts.

- Easy inspection of impeller.

- Large diameter solids handled . up to 60 mm.

- High resistance. to abrasive liquids the wear plate is easily replaced and impeller are also available with ceramic coating

- Easy to install:- only the suction hose is immersed in the liquid, The pump can be set up high and dry in the most convenient position for inspection and maintenance.

- Easily replaceable wearing parts one or more times to get the original performance.

Advantages

- Self priming

- Compact in design

- Can handle solids

- Can use with diesel engine

- Sturdy and strong construction for outdoor application

Range of Performance

- Mud Pumps are available with open and closed type impellers

- Impellers are of three piece design integrally moulded with unique design

- Base shaft is EN8

- It is moulded with PP and sleeved impellers

- Compatible with 95% of aggressive chemicals & corrosive chemicals

- Single piece unique design

- Anti-rotation impeller unlocking system

- Rotatable universal flange

Capacities :

- 0.5 HP to 20HP

- 500 – 60,000 LPH

- Available with open and closed impellers

- Can be fitted with any standard motors

- Suitable for highly corrosive liquids

- Available Material – Poly Propylene (P.P.), M.S., C.I., S.S.