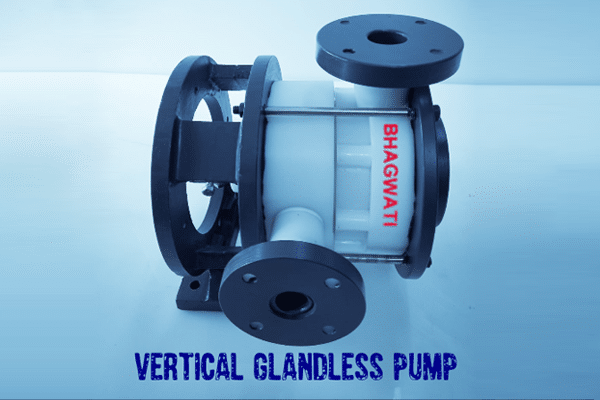

Best Manufacturer of Vertical Glandless Pump in India.

We bring forth a wide range of Vertical Glandless Pumps, which have the finest performance, reliability, and corrosion resistance. Our company is widely recognized in the industry for our suitable supplies of the quantities. It is always been installed in the vertical position. Bhagwati Engineering is a manufacturer of Vertical Glandless Pumps in India. The design of the Vertical Glandless Pump is such that the requirement for any form of motorized seal or chock-a-block gland is eradicated by allocating a controlled leakage of the liquid that is being pumped to return to the suction tank by the route of an overflow connection in the upper body of the vertical glandless pump.

Vertical Glandless Pump is mounted outside the suction tank which is not submerged type but is in solid escalated construction in order to make it stand for corrosion. Vertical Glandless Pumps are manufactured & Supplied at varied ranges with the finest quality in different countries like Bangalore, Chennai, New Delhi, Gujarat, Pune, India & Mumbai.

Operation Advantage of Glandless Pumps

- The obvious main advantage is the removal of problems arising from the use of mechanical seals, stuffing boxes, and internal bearings.

- The ability of the pump to run dry removes one cause of breakdown which is often attributable to the human element this feature is very useful in processes requiring continuous transfer of a corrosive liquid with a high degree of reliability e.g. Disposal of acid effluent.

- The glandless pumps lend themselves to processes incorporating automatic control of a pump discharge valve. The “controlled leakage” acts as an integral bypass. The pump suffers no ill effects if the discharge valve is partially or fully closed.

- The most important gains to be derived from the use of glandless pumps are in the sphere of maintenance and consequent reduction in downtime production losses. Normal maintenance on the glandless pump is confined to lubrication of the driving

The Salient Features of Vertical Glandless Pump

- No mechanical seal, stuffing box and internal bearings provided.

- No maintenance since the pump can even run dry indefinitely as there is no packing, bushes or internal Bearings.

- Reduction of downtime production losses in view of above features.

- All the wet-end parts are in solid molded construction to with stand corrosion and erosion.

- The impeller is semi-open type used in our all-vertical pumps to suit both clear and polluted fluids.

- Pump mounted outside the suction tank and is not submerged type.

Range of Performance

Because glandless pumps do not have any packing bush or internal bearing, full advantage can be taken of available drive speeds. The pump may be run at 1450 and 2900 RPM respectively and a range of impeller diameter for each pump size gives a wide spread of performance.

In general the range cover flow up to 100m3/hr. and discharge head up to 50 meters.